|

|

|

|

|

Overview

|

Different power sources, different communication speeds, different boards, identical assembly, identical operation from the software point of view, both deal with their attached single Kellers in digital mode. The CDi1 talks to the computer and to its Kellers at 9600 baud as the CDi3 does the same at 115200 baud, over 10 times faster. The CDi1 is a very old board, however, the potting process preserves its integrity quite well so it can still be used now or in the future. The "zombification" of the DS1386 RTC chip ensures the perpetuation of both devices well into the future as the *6Z assembly process described in this page adds decades to the service life of both devices. Other than having to change batteries every 8 to 10 years there is nothing else to do, in other words, maintenance is no longer required!

|

|

New CDi1/CDi3 Assembly Method *6Z Pictures, August-September-October 2018

|

- 24th Anniversary Edition Assembly Method!

- Operation "flip the plastic" places the battery compartment at the top of the assembly so the batteries can be changed without having to destroy the outer PVC box. The pictures in this section document this new assembly method, it is named *6Z, the "star" refers to the method itself, the "6Z" refers to the "zombified" DS1386 RTC chip. The old assembly method is documented in the next section below.

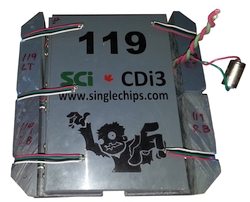

- So two of the original digital P7s #118 and #119 which looked like this in June 2011, and one original analogue P5 #70 which looked like this in the spring of 2005 get a facelift! In addition to the facelift, the old analogue P5 also goes digital and so gets its real name back, and that is, of course, CDi1!

- Obsolete! The CDi1 row of pictures below show how to add digital capability to an old P5 board and the *6Z related.

- The CDi3 rows of pictures show the necessary changes to convert a 2010 P7MAIN board to a CDi3-class board and the *6Z assembly.

- So the major steps are:

- Pot the board in its own compartment first

- Pot the board compartment at the bottom of the PVC box

- Connect the elbows

- Attach the battery compartment and finish the wiring

- Pot the battery compartment

- Test, test, test!

|

|

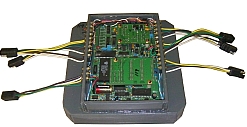

Old P7 Proto (CDi3) Board Assembly Method Pictures, June 2011 (Obsolete)

|

- All air is vacuum-evacuated from both the battery and board compartments while the potting compound sets. Once the wiring is finished and tucked-in neatly, the entire assembly is potted the same way.

- Since no air or very little air remains, the assembly is rendered incompressible.

|

|

|

|

Copyright © 1991-2026 AdamG

Last Update: Tuesday, July 06, 2021 2:53:21 PM

|