CDi3.FTe and CDi3.RMe, Submersible, Universal, Gas Field Controllers

CDi3.FTe, uses 2 Keller singles to calculate flow across the camco box.

Click [+]

Click [+]

CDi3.RMe, formerly CDi3.P7, uses a Keller differential and a Keller single to calculate flow. Click [+]

TemporarilyIndefinitely shelved, not for sale. Locked and put away at LoggerLand5, partial unlock code is "neena". Adam,2017/10/282017/11/25. Additional information above what is shown here is only available to SCi.RS members. Adam, 2018/Jan/05.

- Application software for both units is CDiComm.

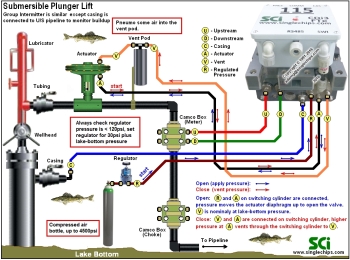

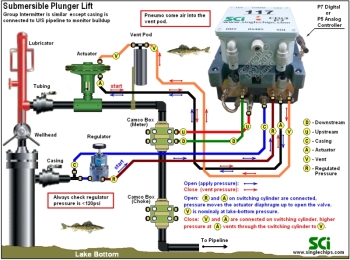

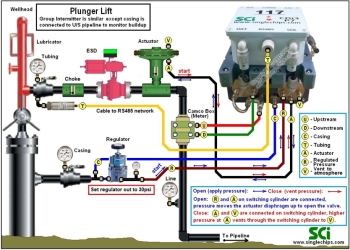

- Designed to be perfectly comfortable at the bottom of Lake Erie, can be used as a line controller, plunger lift, intermitter, etc.

- All Keller-digital pressure measurement, universal gas field controller, 11"x11"x11" cube, implements Keller comms protocol.

- Fully-on, fully-off type of controller. Wakes up, reads everything, stores everything, operates the switch if it has to, and goes back to sleep 2.1 seconds later.

- Programmable interval from 1 minute to 24 hours, with one minute resolution. Due to this operating mode, it can run without recharge for years, click to download power consumption comparison spreadsheet.

- Supports RS485, master-slave, wired or wireless networks at up to 115.2Kbits/sec, has local RS485 network to "talk" to its Keller pressure transmitters at up to 115.2Kbits/sec.

- State-of-the-art PA10LHX singles and PD10LHX differential Kellers, all Hastelloy C276 construction, sourced from Keller in Switzerland.

- Field-replaceable switching cylinders, pressure transmitters.

Typical Applications

- The original plan for the FTe version of the CDi3 was to use a solenoid and a single pressure transmitter to measure flow, like this, but because of the stunning performance of the Keller transmitters in digital mode, decided to use two single transmitters instead. These single Kellers have Hastelloy front ends, and as such are sour gas safe. Because the resulting system is powered by compressed air, no parts are exposed to sour gas except for the pressure transmitters. The two FTe switchers installed October 2016 are modified P7s, originally built in 2010, in the field since June, 2011. Besides the obvious flowmetering function of either unit, there are two additional routine functions, a) plunger lifts with or without a plunger on individual wells and b) group intermitters, also known as programmable chokes for groups of wells. Production optimization of the welbore means using a plunger lift to lift fluids, production optimization of the gathering system means using an intermitter to move fluids along the gathering system or to hold back production of fluids.

- A production optimization paper was written in 2000 by one of our own, Dan Sparkes, the PDL/CDi bible is now online in html.

- A plunger lift, as applied at lake bottom, switches an individual well on and off approximately 18 times as often as an intermitter, a typical plunger lift cycle time is 2 hours, a typical intermitter cycle time is 36 hours.

- A single tank of compressed air, filled to 3,000 psi, will last for 100 days in a plunger lift application, in other words, there is enough air in a single tank for 1200 cycles. The same system in an intermitter application has enough air for 1200x36=43,200 hours or 1,800 days or 4.9 years!!!...

- ...and that means, for the first time EVER, it is now possible AND economical to use an intermitter at ANY location at the bottom of lake Erie...

- Installed plunger lifts and intermitters in spring/summer 2014 currently just out of consecutive winter #3, haven't touched a solenoid since...

- ...and that means, the solenoids we use are good, before repairs are necessary, for at least 13,140 cycles... which in a typical 36-hour cycle, east lake Erie intermitter application is... 13,140x36=473,040 hours, or 19,710 days, or 54 years...

Typical Application Diagrams

Communication Sample Screens

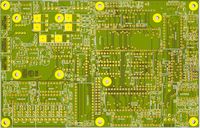

CDi3.P7 Board

Reading (Differential) Cylinder, RMe Version Only

|

||

- 316L cylinder contains a PD10 series Keller differential transmitter and its Hastelloy housing, a forward check valve to protect it from forward spikes, and a 10,000psi penetrator originally sourced from Impulse in California (now a Teledyne Company).

- Cylinder mechanical drawings, PD10 assembly drawing and Hastelloy PD10 housing half.

Switching Cylinder

|

||

- 316L cylinder contains a latching type of solenoid, sourced from Burkert in Germany and a 10,000psi penetrator originally sourced from Impulse in California (now a Teledyne Company).

- The solenoid can switch at pressures of up to 140psi, so it is meant to be supplied through a pressure regulator. The lake operation has had a 20-year period of successfully using these 6V, low-power, media-isolated, latching type of valves.

- Waterproof, quick connectors allow very fast change-out of the entire cylinder in the field.

- The solenoid is used as a pilot valve to operate a pneumatic actuator which in turn does the actual well switching.

Keller Digital Singles

|

||

- Keller PA10 series, 0.05%FS-class-over-temperature pressure transducer, coupled with a Xemics XE8805A-based (now Semtech) board.

- Hastelloy C276 business end, all other metal 316L, 4-wire connection, 2 committed to power, the other 2 for either digital communication or analog output, mechanical pdf drawing here.

- See this page for more info on the Kellers.

PVC Frame

|

||